FTP air handling units represent an important contribution to the improvement of our living environment.

The result of FERROLI’s professionalism and years of experience, they are an important point of reference. The quality of construction and the components used are guarantees of reliability, functionality, and efficiency.

Designed to operate at low, medium and high pressures, FERROLI FTP units are made using a modular system that includes 18 sizes and can thus satisfy a wide range of flow rates.

The normal configurations of the FERROLI air handling units are not suitable for operation in explosive atmospheres.

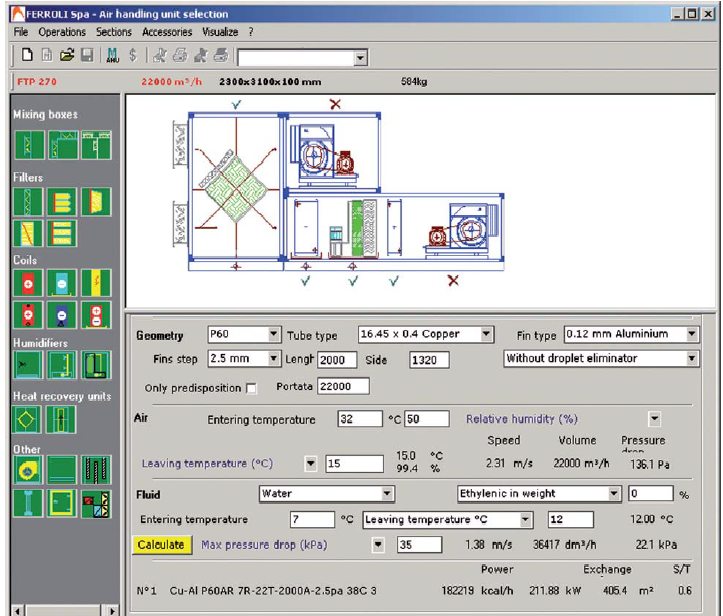

SELECTION PROGRAM

AIR FTP is a selection software that was designed to propose with extreme simplicity a functional, construction, and economic framework for the requested unit.

It is a practical and complete tool that is indispensable for determining the dimensions of air handling units. Due to its ease of use, completeness of data, and number of solutions proposed, AIR FTP has been applauded by many thermal engineering offices, to which it is provided upon request. Specialized Ferroli personnel are available to provide information or training on how to use this software.

CE Marking

All of the FERROLI air handling units are built in observance of applicable EEC Directives 89/392, 91/368, 93/44, 93/68, and 73/23 and are, therefore, in compliance with the “essential Health and Safety requirements” prescribed by these directives. The units are designed in observance of the above-mentioned standards and, therefore, they have been equipped with a series of prevention and safety devices suitable for satisfying the requirements of the standards:

• Safety and protection nets on the moving parts.

• Safety micro-switches.

• Lights for the internal illumination of the machine.

• Handles that can also be opened from inside the machine.

• Rounded corners and absence of any sharp parts.

Adhesive signs that are highly visible due to their size and color are applied to the machine’s external casing to indicate possible dangers due to moving parts and electric current.

Structure

Built with UNI 9006 anodized extruded aluminum sections joined to form a frame by means of diecast aluminum or nylon corner joints and double-layer panels, insulated with high density mineral wool (80-100 kg/m3) or foamed polyurethane with a thickness from 23 to 48 mm, available in the normal

configuration or the thermal size.

The panels can be made by combining different types of materials:

• Z175 galvanized steel sheet.

• Prepainted steel sheet.

• Peraluman sheet.

• AISI 304 stainless steel sheet.

The panels are attached to the frame with stainless steel or galvanized steel screws and are equipped with self-adhesive seals.

The inspection panels are mounted on hinges and equipped with a double handle for closing (from inside and outside).

Base

The base is made of a continuous girder, thick galvanized steel sheet, and press formed pieces with a cross-section the shape of a square bracket to ensure a high level of structural rigidity to allow it to be handled and transported in complete safety on the building site. Each section is equipped with eye bolts or holes for the insertion of hoisting crossbars.

Heat Exchange Coils

The heat exchange coils are removable so that they can function with water, mixtures with glycol, direct expansion, or steam. They are made with a frame consisting of die formed steel sheet, and the seal is tested in water with dry air at a pressure of 30 Atm. In the standard version they are made with copper tubing and a mechanically expanded aluminum pack with louvers. Upon request they can be made with steel or stainless steel tubing or and a pack with louvers made with copper, tinned copper, or stainless steel. The spacing of the louvers is 2, 2.5, 3, 4, 5, and 6 mm. The headers normally have threaded connectors, but they can be provided flanged as well.

Air Filtration

This selection is essential for ensuring the quality of the treated air. The available type covers allneeds: from roll filters to common plan, rigid or soft bag filters, absolute filters with an efficiency level of 99.999% DOP, according to the customer’s specific needs. They conform to the usual requirements that they be self-extinguishing and their efficiency is certified in compliance with the most important standards (EUROVENT,AFI, ASHRAE, NSB, ETC.). Also, activated charcoal filters, germicide lights, and other types of equipment are available upon request. They can be placed in one or more sections of the unit according to the type of filtration.

The importance must not be undervalued of choosing a type of filtration that is suitable for retaining the impurities in the air with variable dimensions and characteristics to obtain, after treatment, the conditions required for the environment to be served. The table shows, in a schematic form, the type of filter that is suitable for treating the impurities present in the air and specifies its classification according to the most current standards.

Heat Recovery Units

The different types and brands of heat recovery units on the market can be provided.

They have been chosen by our Technical Office in close collaboration with the best national and foreign manufacturers.The following are the ones that are used most frequently:

Static type

Cross-flow units with aluminum (or stainless steel) plates sealed in such a manner as to guarantee the total absence of contact between the outlet air and the inlet air; heat pipe units made with one exchanger that is exactly similar to a coil, with copper tubing and aluminum louvers, charged with a two-phase liquid

Rotary type

With rotating drum, available in both a standard aluminum version for the recovery of sensible heat and a hygroscopic version for the recovery of sensible and latent heat.

Devices for controlling the rotation speed of the drum are available upon request.

Normally they are inserted inside the air handling unit so as to allow easy maintenance, in sections that sometimes come complete with control dampers, allowing the inclusion of mixing chambers or bypasses to operate completely with outside air, circulation, or free-cooling.

Droplet Seperators

The droplet separators are made with a frame and louvers of different shapes and materials and can be installed in the versions that are available:

• With louvers having 3 folds and a frame made of Z175 galvanized steel sheet.

• With louvers having 3 folds and a frame made of AISI 304 stainless steel sheet.

• With louvers having 3 folds made of aluminum sheet and a frame made of AISI 304 stainless steel.

• With louvers having 2 folds made of polypropylene and a frame made of AISI 304 stainless steel.

• With louvers having 4 folds made of polypropylene and a frame made of AISI 304 stainless steel.

Collection Tray

Collection trays are installed in all the selections with components that use or that can form water: cooling coils, humidification, heat recovery units, and droplet separators.

They can be made of galvanized steel sheet or AISI 304 stainless steel sheet and are equipped with one or more threaded loading and unloading headers.

The placement of the trays inside the unit’s casing makes it thermally insulated, thus avoiding the dangers of freezing the liquid contained in the units that are located externally. Antifreeze electric elements can be installed in their interiors for greater safety.

Dampers

The standard version of the dampers is made with a frame of galvanized sheet and hollow-core louvers of extruded aluminum, complete with seal. The opposed louvers are moved by nylon wheels located inside the damper and are equipped with manual control or a pin for servo control.

On request the dampers can be made completely out of aluminum or, when installed, can be made with wheels outside of the air flow and sliding metal seals that guarantee, when closed, the low-pressure seal.

Humidification

This series of air handling units has been equipped with sections for housing all the most common humidification systems: with evaporating pack, with nozzles, with steam, and with atomization.

With steam:

This humidification system can be realized both by installing an autonomous steam generator and by using the steam supply line. In both cases normally our section is designed for the installation of both types of steam delivery.

With evaporating pack:

This humidification system consists of a cellular pack made of cellulose, is impregnated with phenolic resins, is contained in a metal frame, and has a water distributor in the upper part. The spacers that are available are 100 and 200 mm. The section can employ

either water discharge or a re-circulation pump with a filling valve, an overflow, or a bleed-off.

With nozzles:

This system, which is also commonly known as a “scrubber system,” consists of a series of self-cleaning spray nozzles installed on one or two tubes. The system is designed with a sealed double chamber and can employ either water discharge or a re-circulation pump.

With atomization:

This system consists of a series of special nozzles known as “atomizer heads” that mix water and compressed air to turn the water into a thick fog (aerosol).

Silencers

The silencers can be installed both inside and outside the unit and are displaced both at the outlet and the inlet. They are essential for reducing the noise produced mainly from

the operation of the fan. They are available in different lengths from 750 to 2000 mm and

are constructed with sound-proofing elements consisting of multiple layers of mineral wool contained in a housing of perforated metal sheet. The external surfaces of the sound proofing elements (those that are in direct contact with the air) are contained in

a composite film to prevent it from flaking or being chipped.

Fans

Double inlet centrifugal type fans with blades curved forward or backward, according to the total pressure necessary, with an impeller that is statically and dynamically balanced according to the values specified in the standards, which employ bearings lubricated

for life with a minimum life of 50,000 hours. The models with blades curved backward are also available with a flow rate regulator on the intake.

The size of the fan and its rotation speed are chosen with special care by our Technical Office which, taking into consideration the required performance, researches the maximum yield possible and the lowest level of acoustic emission.

Motors

The motors are asynchronous three-phase motors with squirrel-cage rotor, IP55 protection rating, and class F windings. They are in compliance with standards IEC 34-1 and IEC 72 (CEI 2 – 3 no. 355 – UNEL 131132-71-B3 UNEL 13118-71) and with the national Italian standards (VDE, NFC, NBNC, BS, SEV, NEN, etc.). They are installed on a slide that allows them to be firmly anchored and makes it possible to adjust the tautness of the driving belt.